Air-cooled chillers

NOMINAL COOLING CAPACITY 1,8 - 4,4 KW

Developed from the TAEevo range expertise, the TAEevo TECH MINI has been significantly enhanced through key technical updates: a new finned coil evaporator, a robust structure with eyebolts, and advanced electronic controls. It offers a perfect balance of high reliability, compact dimensions, and high efficiency—ideal for cooling smaller industrial processes.

Maximum reliability

The design of the MINI units combines a commitment to class-leading performance with top-notch component reliability. The innovative finned coil evaporator ensures dependable operation even in demanding applications. Additionally, the non-ferrous hydraulic circuit enables the MINI chillers to handle fluids that are aggressive to carbon steel, maintaining the highest quality and cleanliness of the process fluid.

Easy installation

Thanks to their compact dimensions, MINI units can easily be installed even beneath a workbench. Their robust structure with eyebolts allows for lifting the unit using straps with hooks. Moreover, the dual frequency design of the MINI 03 model makes it suitable for both 50Hz and 60Hz applications.

Easy maintenance

The logical layout of components, the simplicity of the refrigerant circuit, and clearly numbered electric cables simplify checking and maintenance operations, which can even be performed while the unit is running. The disassembly of the condenser air filters for periodic cleaning is facilitated by an interlocking fastening system. Models M08-10 are equipped with a green light that remains on under normal operating conditions and turns red in alarm conditions.

Extended operating limits

The wide operating limits allow MINI units to function even under extreme conditions. The maximum water inlet temperature is 35°C and the minimum water outlet temperature is 0°C. TAEevo TECH MINI can also operate in ambient temperatures as high as 45°C.

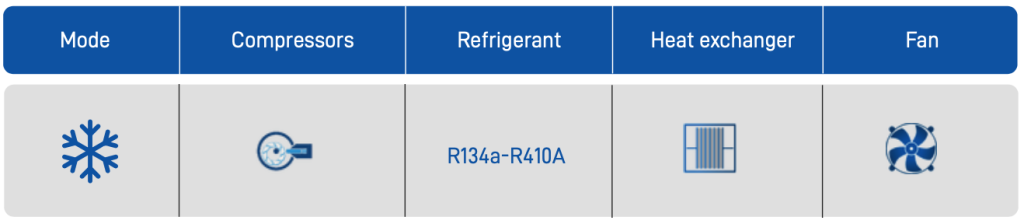

Technical features

Benefits

- Innovative evaporator with finned pack and in-tank configuration, featuring low pressure drops and reduced sensitivity to fouling

- Refrigerant fluids (ODP=0) R134a (mod. M03) and R410A (mod. M05-10) ensuring higher performance thanks its outstanding heat conductivity

- Reinforced structure with eyebolts allows lifting the unit by means of straps with hooks

- Atmospheric pressure hydraulic circuit built with non-ferrous materials

- Water buffer tank in polyethylene equipped with a drain valve a water filling and overflow connections and a visual level indicator

- Safety water by-pass

- Advanced XR60CX microprocessor control

- General alarm free contact and remote ON / OFF digital input

- Easy installation, use and maintenance

- SEPR HT Tier2 compliant

Options

- Close control temperature version (mod. M08-M10): this version offers extremely precise regulation of the outlet water temperature (hysteresis± 0,5 °C)

- Brine version: suitable for low outlet water temperature (Tw out min=-5 °C)

- P5 Pump (mod. M08-M10): peripheral non ferrous pump (5 barg available head pressure)

- Tank level switch (mod. M08-M10)

- Multipole industrial connector (mod. M08-M10)

- Hydraulic disconnect system (mod. M08-M10)

- Stainless steel frame

Kits

- Water filter kit

- Automatic hydraulic by-pass kit

- Antivibration mountings kit

- Dynamic set point kit

- Wheels kit

Sectors of application

Plastics

Chemical & Pharmaceutical

Food & Beverage

Laser

Machine Tools

Wineries

Plastics

Chemical & Pharmaceutical

Food & Beverage

Laser

Machine Tools

Wineries

Certifications