Senyorita

The Challenge

The customer initially focused on producing potato chips, corn snacks, and biscuits. Rapid growth required the expansion of production facilities and product diversification. A leading FMCG group in the Middle East and North Africa later acquired the company, significantly enhancing operations, management, and restructuring the administrative structure.

The project involved providing a reliable cooling solution for packaging machines used in biscuit production. The cooling capacity required was 25 kW, with water temperatures ranging from 0°C to -5°. This was part of a replacement plan for an old German-brand chiller (DTE).

Challenges

- Service Contract with DTE: The plant had three chillers under the DTE brand, complicating the replacement process.

- Familiarity Gap: Limited awareness of MTA chillers among plant management, who were more familiar with Trane.

- High Production Demands: Reliable cooling was critical to maintaining product quality and operational efficiency.

The Solution

Following a detailed site visit and survey to understand the manufacturer’s specific applications, facilities, and temperature requirements, we successfully received their official RFQ.

Proposed Solution

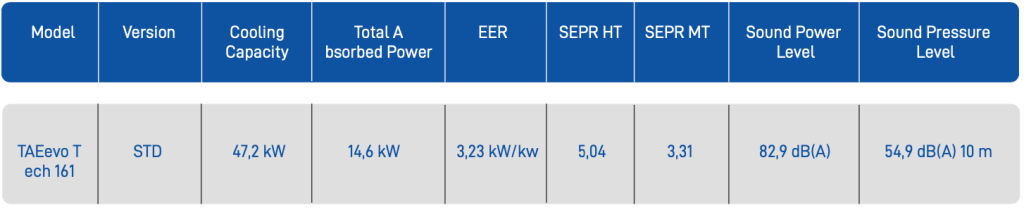

To meet their needs, we have proposed: Two Units of MTA TAEevoTech 1002 – Equipped with an Integrated P3 Pump and Manual Filling Kit

Key Advantages of Choosing MTA

- Innovative In-Tank Evaporator Technology: Ensures smooth and consistent cooling performance.

- Advanced Evaporator Design: Utilizes immersed finned coil for optimal efficiency.

- Superior Tank Durability: Features a robust carbon steel tank for long-lasting performance.

- Certified Quality: Eurovent-certified, ensuring compliance with high industry standards.

- Efficient Lead Time: Delivery within 4-6 weeks.

- Best Lead Time

- Flexible Incoterms: Delivered Duty Paid (DDP) for streamlined logistics.

- Comprehensive Aftermarket Support: Strong local support in Egypt to address any needs promptly.

- Lowest Running Costs: Designed for energy efficiency and cost-effectiveness.

- Value-Driven Pricing: Although MTA’s pricing is higher, it delivers exceptional value and reliability.

Strong MTA reference in Egypt, Especially TAE chillers, to build trust in the proposed solution.

The Result

- Successful Win: MTA successfully secured the purchase order for the chillers.

- Repeat Business: The customer placed an additional order for a fourth chiller to cool another printing machine.

- Seamless Integration: MTA’s TAE chillers were installed and connected to each printing machine, with full support from our service department

during startup, ensuring flawless operation. - Ongoing Partnership: After the successful installation, the customer requested recommended spare parts and is considering a yearly service

contract to maintain peak performance.

New Projects: We're now working on new projects with this valued customer.