PharmaChill / Low-Temp Pharma Cooling

The Challenge

A leading multinational pharmaceutical manufacturer required a heavy-duty cooling solution capable of delivering extremely low process temperatures of -25°C while operating efficiently in ambient conditions as high as 46°C. The system needed to support three critical process machines simultaneously without compromising performance or reliability.

Industry: Pharmaceutical

Application: Low-temperature process cooling for sensitive production equipment

The customer initially requested a single unit capable of delivering 80 kW cooling at sub-zero temperatures using a screw compressor. This specific configuration was challenging to source. Additionally, the units needed to be compatible with the factory’s Building Management System (BMS) and flexible enough for both indoor and outdoor installation, adding further complexity to the project.

Challenges

- Uncommon Temperature Range: Required output temperature of -25°C at 46°C ambient, a combination rarely achievable with standard equipment.

- Difficult Specifications: The requested configuration (screw compressor, single 80 kW unit) was not readily available.

- Installation Flexibility: Required reliable operation both indoors and outdoors.

- BMS Integration: Needed seamless connectivity with the customer’s BMS system.

Considerations for the Replacement Plan

- Performance Stability: The solution needed to consistently maintain extremely low temperatures even in peak summer conditions.

- Redundancy: A redundant system was preferred to minimize risk of process interruptions.

- Certifications: Eurovent compliance was required to meet internal and regulatory quality standards.

- System Integration: Smooth BMS compatibility was critical for operational control and monitoring.

The Solution

To address these unique challenges, the customer was introduced to MTA’s TAE LWT series, engineered specifically for low-temperature applications while ensuring reliable performance in high ambient environments.

Proposed Solution

- 2 Units of MTA TAE LWT 802 Air-Cooled Chillers

- Each unit delivering 40 kW

- Integrated P3 Pumps and RS485 Serial Communication Kits for seamless BMS integration

Key Advantages of Choosing MTA

- Low-Temperature Capability: Designed to achieve -25°C process water temperatures in 46°C ambient environments.

- Redundant Design: Dual-unit configuration provides enhanced efficiency, better load distribution, and backup during maintenance.

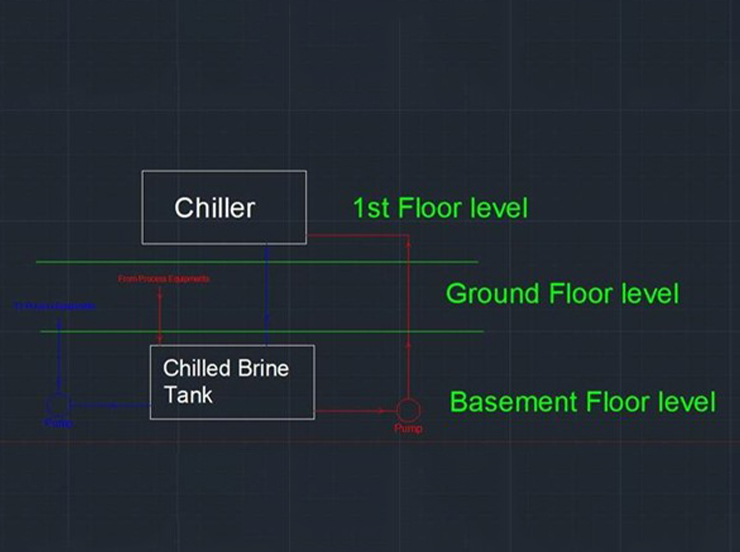

- Compact & Integrated: Built-in pumps and tanks simplify the installation process.

- Flexible Placement: Reliable for both indoor and outdoor setups without performance loss.

- Certified Reliability: Eurovent-certified for compliance and verified performance.

- BMS Ready: Full compatibility with the factory’s BMS through RS485 interface.

The Result

- Successful Project Award: Secured the order for two TAE LWT 802 chillers, complete with P3 pumps, RS485 kits, and a two-year spare parts package.

- Tailored Cooling Solution: Delivered a robust and flexible system meeting the manufacturer’s strict low-temperature and reliability requirements.

- Operational Confidence: Organized a factory visit to MTA’s Tribano and Conselve facilities, reinforcing trust in product quality and service standards.

- Redundancy and Uptime: Dual chiller configuration ensures uninterrupted production, minimizing downtime and safeguarding sensitive pharmaceutical processes.