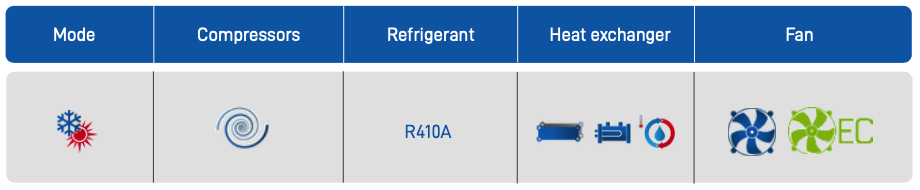

Air cooled reversible heat pumps with scroll compressors.

Nominal cooling capacity 12,8 - 88,4 kW Nominal heating capacity 11,1 - 84,3 kW

The HAEevo TECH reversible heat pumps are high efficiency units specifically designed for wine industry, and generally for all process applications when high performance, continuous operation and reduced management costs are the main requirements.

The oversized heat exchangers surfaces and optimised scroll compressors ensure high performances, maximising the energy savings. The wide numbers of options available makes the units highly customizable, suitable to satisfying any type of plant solution.

All units are compliant with the limits imposed by the ErP Regulation for seasonal efficiency ratio SEPR HT and SCOP.

Technical features

Standard features

- Hermetic scroll compressors;

- Compressors crankcase heater and phase monitor;

- High-efficiency finned coil evaporator with copper tubes and aluminum fins, installed inside the carbon steel water storage tank;

- Axial AC fans;

- Air cooled condensers with copper tubes and aluminium fins protected by hydrophilic treatment;

- Condenser air filters;

- Electronic expansion valves;

- 4-way refrigerant cycle reversing valve;

- Storage tank;

- Single water pump with medium head pressure (P3);

- Internal hydraulic by-pass between the inlet and outlet connections;

- Electronic level sensor with water conductivity function;

- High and low refrigerant pressure switches;

- Parametric microprocessor control;

- IP54 electrical protection rating.

Options

- Single water pump with high head pressure (P5);

- Single water pump with medium head pressure (P3) suitable for open hydraulic systems;

- Non-Ferrous hydraulic circuit, suitable for aggressive process fluids (finned coil evaporator with copper tubes and fins installed inside the AISI304 water storage tank);

- Anti-freeze protection heaters for evaporator and pump (if included);

- EC brushless fans.

Benefits

- Seasonal energy efficiency compliant with ErP Directive 2009/125/EC;

- Scroll compressors ensure high efficiency and performances, maximising the energy savings;

- Evaporator with in-tank configuration specifically designed for process cooling applications. It allows high flow rates with low pressure drops and compatibility with impure process fluids even with high percentages of glycol;

- Oversized water storage tank, useful to compensate the instability caused by sudden changes of the required load;

- Extended operating limits (chiller mode): Tw in max = +35 °C; Tw out min = -10 °C; Tamb max = +46 °C; Tamb min = -10 °C;

- Extended operating limits (HP mode): Tw out max = +55 °C; Tw out min = +30 °C; Tamb max = +20 °C; Tamb min = -10 °C.

Kits

- Manual filling tank kit: suitable for at atmospheric hydraulic circuits;

- Automatic filling kit: suitable for pressurized hydraulic circuits;

- Glycol filling kit: suitable for pressurized hydraulic circuits;

- Automatic hydraulic bypass kit: includes adjustable pressure relief valve;

- Condenser air filters;

- LED remote display;

- LCD remote display;

- RS485 Modbus interface for connection to supervisor systems;

- xWEB300D PRO to monitoring, control and register data, based on “WEB server” technology;

- Modularity kit, for master/slave system management (up to 5 units).

Sectors of application

Airports & Stations

Cinemas, Theaters & Museums

Hospitals

Hotels & Restaurants

Leisure & Sport Centers

Offices

Public Buildings & Schools

Shopping Center

Airports & Stations

Cinemas, Theaters & Museums

Hospitals

Hotels & Restaurants

Leisure & Sport Centers

Offices

Public Buildings & Schools

Shopping Center

Certifications