Silver Edge Technology

The Challenge

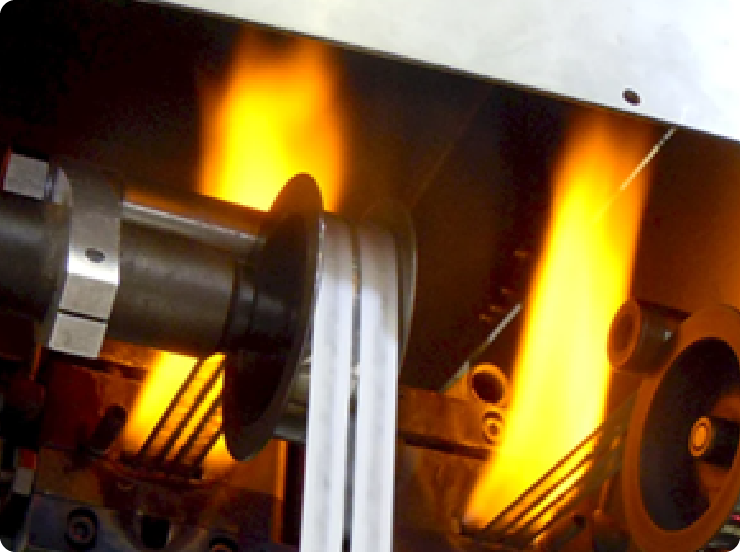

A prominent Egyptian manufacturer of disposable and professional razor blades needed a replacement for their aging chillers, which were essential for cooling their advanced injection molding machines and a coil-to-coil furnace. These processes, crucial for hardening and tempering razor blade strips, demanded uninterrupted and reliable cooling to maintain high production rates.

The manufacturer initiated a competitive bidding process, inviting proposals from established brands in the market. Introducing a new brand, such as MTA, to the plant management posed a challenge due to unfamiliarity and the reliance on existing systems.

Challenges We Faced

- Reliable and consistent cooling to meet high production demands.

- Compatibility with critical manufacturing processes, including injection machines and coil-to-coil furnaces.

- A trusted partner offering strong after-sales support and service.

- Energy-efficient solutions for long-term cost savings.

The Solution

To address the manufacturer’s need for a reliable and efficient cooling solution, MTA proposed a tailored solution:

Proposed Equipment

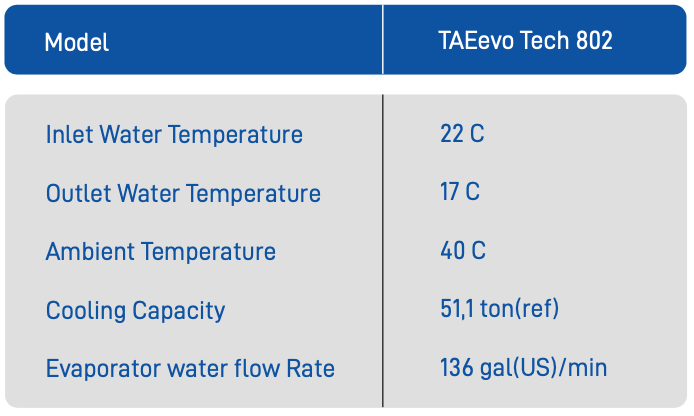

Three Units of TAEevoTech 802, designed to meet the high demands of their process cooling applications, Equipped with :-

- An integrated P3 pump for optimal performance.

- Manual Filling Kit for easy operation.

- Factory-fitted soft starter for smooth start-up.

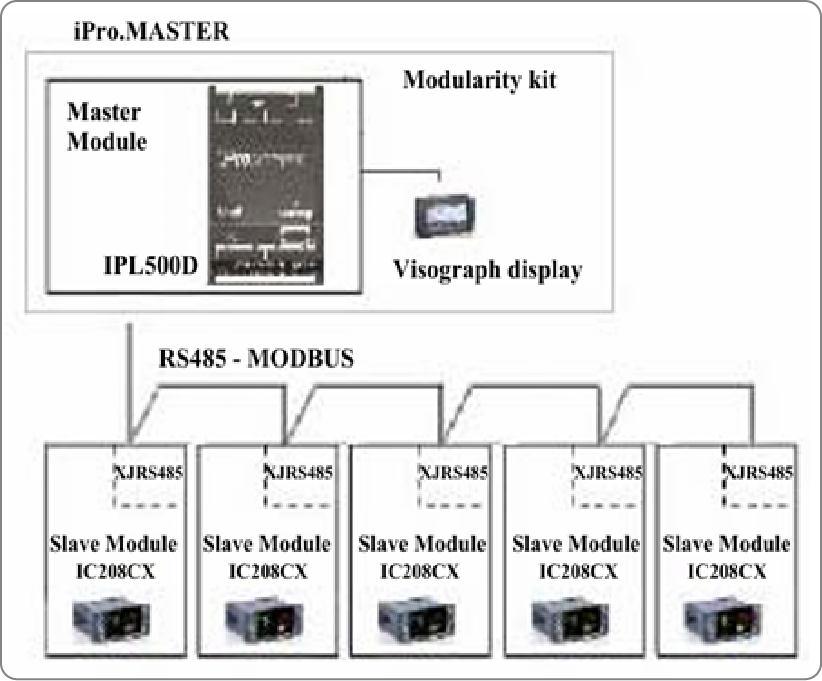

- RS485 Serial Board for supervision and modularity systems.

- Modularity Kit for IC208CX (master unit only) to enhance system flexibility.

Why Choose MTA?

Innovative In-Tank Evaporator Technology

- Ensures smooth and consistent cooling performance.

- Uses an immersed finned coil evaporator, superior to BPHE and Shell and Tube designs.

Certified Quality

- MTA chillers are Eurovent certified, guaranteeing top performance and energy efficiency.

Quick Lead Time

- MTA offers a lead time of +6 weeks, significantly faster than competitors’ +18 weeks.

Extended Warranty

- A five-year warranty provides added assurance of reliability and support.

Strong Aftermarket Support

- Comprehensive service and spare parts availability for seamless operations.

Lowest Running Costs

- Designed for energy efficiency and long-term operational savings.

Building Trust

To overcome the challenge of introducing a new brand, we leveraged MTA’s strong references in Egypt, particularly the proven performance of TAE chillers, to instill confidence in the proposed solution.

This approach not only met the manufacturer’s cooling needs but also positioned MTA as a reliable partner for their high-production demands.

Performance

The Result

MTA Wins Over Competitors!

Key Achievements

- Secured the purchase order after a competitive bidding process.

- Finalized a five-year annual service contract to ensure optimal performance and long-term reliability.

- Delivered a customized spare parts recommendation to support continued efficiency and uninterrupted operations.

- Following this success, the customer’s trust in MTA has opened doors to further collaboration, including discussions on a new project with one

of their competitors. - This milestone reinforces MTA’s reputation as a leading provider of innovative cooling solutions backed by strong aftermarket