Nile Drip

The Challenge

A leading producer of plastic films for agricultural and packaging applications.

Product Portfolio Includes: Greenhouse Covering Film, Low Tunnels Film, Grapes Covering Film, Mulching Film & Lamination Film

Project Overview

The customer required a reliable cooling solution for their blown film extrusion machines used in the production of plastic films. The project demanded a cooling capacity of 120 TR (one chiller in operation, the other as backup).

Challenges We Faced

- Local Competition: Competitors offering cost-competitive solutions.

- Familiarity Gap: Limited awareness of MTA chillers among plant management.

- High Production Demands: Reliable cooling was critical to maintaining product quality and operational efficiency.

Considerations for Replacement Plan

- Global Collaboration: Ensured alignment with both local plant requirements and global corporate standards.

- Operational Efficiency: Addressed the need for consistent process cooling to maintain product quality and reduce waste.

- Heat Management: Focused on chillers designed for high ambient temperatures.

The Solution

Following a detailed site visit and survey to understand the manufacturer’s specific applications, facilities, and temperature requirements, we successfully received their official RFQ.

Proposed Solution

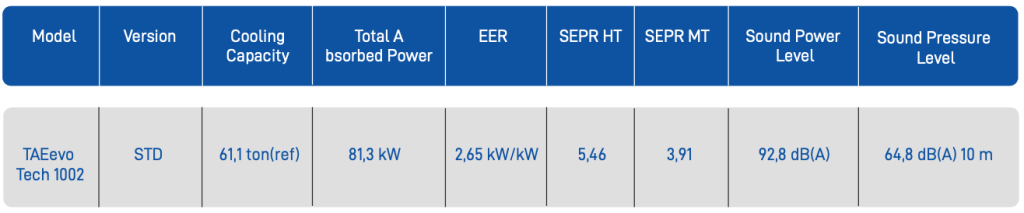

To meet their unique needs, we have proposed: Three Units of MTA TAEevoTech 161 – Equipped with an Integrated P3 Pump and Manual Filling Kit

Key Advantages of Choosing MTA

- Innovative In-Tank Evaporator Technology: Ensures smooth and consistent cooling performance.

- Advanced Evaporator Design: Utilizes immersed finned coil for optimal efficiency.

- Superior Tank Durability: Features a robust carbon steel tank for long-lasting performance.

- Certified Quality: Eurovent-certified, ensuring compliance with high industry standards.

- Efficient Lead Time: Delivery within 4-6 weeks.

- Best Lead Time

- Flexible Incoterms: Delivered Duty Paid (DDP) for streamlined logistics.

- Comprehensive Aftermarket Support: Strong local support in Egypt to address any needs promptly.

- Lowest Running Costs: Designed for energy efficiency and cost-effectiveness.

- Value-Driven Pricing: Although MTA’s pricing is higher, it delivers exceptional value and reliability.

Strong MTA reference in Egypt, Especially TAE chillers, to build trust in the proposed solution.

The Result

- Successful Win: MTA successfully secured the purchase order for the chillers.

- Repeat Business: The customer is planning to add an additional chiller to cool another machine.

- Seamless Integration: MTA’s TAE chillers were installed and connected to each blown machine, with full support from our service department during startup, ensuring flawless operation.

- Ongoing Partnership: After the successful installation, the customer requested recommended spare parts and is considering a yearly service contract to maintain peak performance.